4mm Punch Spiral Changeable Die

4mm Punch Spiral Changeable Die Specification

- Type

- Paper Binding Machinery

- Material

- Mild Steel

- Control System

- Human Machine Interface

- Weight (kg)

- 15 Kilograms (kg)

- Dimension (L*W*H)

- 22*3*5 Inch (in)

4mm Punch Spiral Changeable Die Trade Information

- Minimum Order Quantity

- 5 Units

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About 4mm Punch Spiral Changeable Die

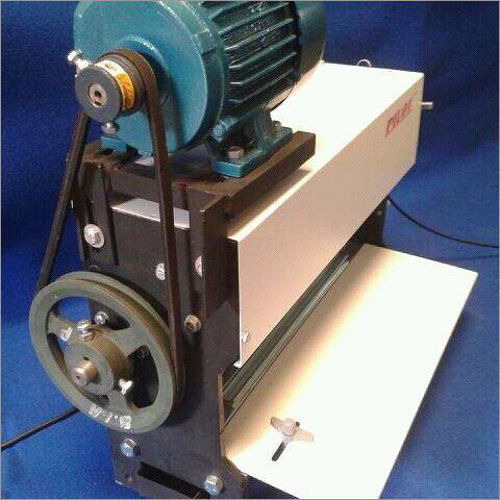

A 4mm Punch Spiral Changeable Die is an essential component used in binding machines to create precise holes for the purpose of spiral binding. Let me break down its explanation for you:

1. What is a Punch Die?

A punch die is a metal tool that is installed into a binding machine to create holes in paper. It is usually made of hardened steel to maintain sharpness and durability over time. The die has a specific size and shape, allowing it to punch consistent holes in materials like paper, card stock, and plastic.

2. What Does "4mm" Mean?

The 4mm refers to the diameter of the holes that the die creates. In this case, it creates holes that are 4 millimeters in diameter. This size is commonly used for spiral binding (also known as coil binding) because it fits the standard size of spiral coils that are used to bind documents together.

3. Spiral Binding (Coil Binding):

-

Spiral Binding involves punching a series of holes along the edge of a stack of paper and then threading a spiral coil (often made of plastic or metal) through those holes. The 4mm holes allow the coil to pass through easily and hold the document together securely.

-

Pitch: The term 4:1 pitch often refers to the spacing of the holes in spiral binding. With 4mm punch dies, the holes are placed at 4 holes per inch, which is ideal for spiral coils. This ensures a tight, secure binding without too much looseness or tightness.

4. Changeable Die:

-

A changeable die means that the die can be swapped out or replaced with another one to allow different hole sizes or binding styles (such as comb binding, wiro binding, etc.).

-

This flexibility is important in commercial and office environments where different types of binding might be needed for different projects. Rather than buying a new machine for each binding style, you can simply change the die to match your binding requirements.

5. Why 4mm Punch?

-

4mm hole size is the standard for spiral (coil) binding, making it one of the most popular choices in binding machines.

-

The hole size ensures that the spiral coil fits comfortably through the paper holes without being too tight or loose, allowing for a smooth, durable binding.

6. How It Works in the Machine:

-

The die is inserted into a binding machine, which is either manual or electric.

-

When you load a stack of paper into the machine and engage the punch mechanism, the machine uses the die to punch 4mm holes through the sheets.

-

Once the punching is complete, you can insert the spiral coil into the holes to bind the document together.

7. Advantages of Using a 4mm Punch Spiral Changeable Die:

-

Versatility: Since the die is changeable, you can punch holes of different sizes depending on the project, making the machine more adaptable.

-

High Quality: A 4mm hole size is suitable for high-quality, professional-looking documents that require secure, neat binding.

-

Durability: These dies are made from strong materials like hardened steel, ensuring long-lasting performance and clean, precise holes every time.

8. Applications of a 4mm Punch Spiral Die:

-

Office environments for binding reports, manuals, and presentations

-

Print shops for high-volume document production

-

Schools and businesses for binding training materials, workbooks, or instructional manuals

-

Calendars and notebooks where spiral binding is a preferred choice

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Spiral Binding Machine Category

Box File Punching Machine

Price 27000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Computerized : No

Automatic Grade : SemiAutomatic

Dimension (L*W*H) : 29*18*27 Inch (in)

4mm Punch Manual Spiral Binding Machine (2 In 1)

Price 8000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Mild steel/aluminium

Computerized : No

Automatic Grade : Manual

Dimension (L*W*H) : 22*13*13 Inch (in)

Automatic Spiral Binding Machine 5mm Punching

Price 26500.00 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Mild Steel

Computerized : No

Automatic Grade : Automatic

Dimension (L*W*H) : 29*18*27 Inch (in)

Automatic Electrical Spiral And Wiro Binding Machine (changeable Die)

Price 24000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Computerized : No

Automatic Grade : Automatic

Dimension (L*W*H) : 29*18*27 Inch (in)

Send Inquiry

Send Inquiry